Raw materials and equipments needed for making briquette:

|

1. Charcoal: Charcoal is carbonaceous material produced by pyrolysis of woody biomass. It can be prepared by partial carbonization of biomass residues like wood, saw mill wastes, forest biomass namely, leaves, twigs and agricultural residues like maize stalk, pigeon pea stalk and weeds.

2. Binding agent: The cheapest binding agent is mud which is available everywhere. Dry soil dominant in clay content also can be used after mixing it with water. While using mud one has to be sure that there is no big size clod or stone in it.

3. The charring drum: It is a simple metallic drum in which biomass is burnt to make charcoal. A 200–litre oil drum can be used as charring drum after putting a gas sealing lid and a chimney.

4. Briquetting mould: This is the most important tool in making beehive briquette. It gives the shape and required compaction to the briquette. The mould consists of a base plate of 5 mm thickness containing 21 iron pegs of 12 mm diameter, a perforated pressure plate and a cylinder of 85 mm diameter. It is very simple to fabricate and easy to use.

|

Steps of making beehive briquette:

Step 1: Collection of biomass – Pine litters, lantana, wild oat, weeds from agricultural field and saw mill waste are the potential biomass for charcoal making. One can go for wood if it is abundant.

Step 2: Preparation of biomass – Sun dry the biomass as much as possible so as to get moisture content preferably below 20% as it will help save the energy of drying while making of charcoal and also charcoal recovery will be high with less amount of smoke. Cutting of biomass in small pieces will further help in quick process and better quality of charcoal.

Step 3: Making Charcoal – Place the charring drum over platform of three bricks arranged in triangular shape. Put the chimney with conical grate in the drum. Fill the drum with biomass by keeping the woody biomass at bottom and loose at top. Fire it from top and go on adding biomass. Allow it to burn for one hour or as long as white smoke comes. When smoke transform to gray or colourless, remove the chimney extension, cover the lid and make it airtight by putting water in the sealing gutter. Allow the drum to be cooled for another two hours or more. Now the biomass has been converted into charcoal. Then take out the charcoal from drum and grind it by a wooden hammer.

Step 4: Preparation of binder – Collect the soil or mud from any agricultural field. Wean out stones or big size clods from the soil. If the soil is dry then mix water to make it sticky so that it can be a good binder.

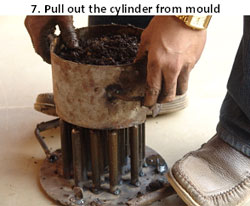

Step 5: Preparing the briquette – Mix thoroughly the ground charcoal with soil at a ratio of 70:30 by volume or 60:40 by weight. Put the cylinder and perforated pressure plate of the mould on the base plate. Fill the cylinder with the mixture and beat it over a wooden plank for compaction. Then takeout the cylinder along with the briquette out from the pegs and put it up-side-down to release the briquette by putting pressure on the pressure plate.

Step 6: Drying of briquettes – Sun dry the briquettes for a week and then store it. It can be burnt efficiently in a beehive briquette stove. One briquette of around 500 grams will burn for 2.5 to 3 hours and gives smokeless blue flame while burning.

Pictorial steps of briquette making

|

|

|

|

|

|

|

|

|

|

||

Cost details: Cost details are presented below which shows that targeting to produce 6000 briquettes per month a profit of Rs. 21,000 can be earned. It is also showing that input cost per briquette is Rs. 6.50. If charcoal is produced in-house then the cost could be much lower.

| 1. Fixed cost monthly | Rs. | Comment | |

| Charring Drum | 208 | Initial cost Rs. 5000 and life two years | |

| Mould | 21 | Initial cost Rs. 1000 and life four years | |

| Total Monthly depreciation | 229 | ||

| 2. Operation cost monthly | |||

| Charcoal | 20000 | For two tons of charcoal needed to produce 6000 briquettes | |

| Labourer @120/day for 4 labourers | 14400 | For making charcoal, preparing mixture, making briquettes | |

| Transportation | 2000 | ||

| Miscellaneous expenses | 2000 | ||

Total monthly cost = Rs. (229+20000+14400+2000+2000) = Rs. 38,629 say 39,000

| No. of briquettes produced: | 6000 Pieces |

| Cost per pieces | Rs. 10 |

| Cost of 6000 briquettes | Rs. 60,000 |

| Input cost | Rs. 39,000 |

| Net profit | Rs. 21000 |

Beehive Briquettes: Beehive briquettes are mainly charcoal briquettes made from char and clay mud mixed in certain proportion. Mud acts mainly as binding agent and reduces the rate of burning. The beehive briquette is a circular shape briquette having diameter of 145 mm and height of 85 mm with 21 holes of 12 mm diameter. Due to the holes, it looks like beehive, thus the name came Beehive Briquette. Dried beehive briquette produces smokeless blue flame during burning for 2.5 to 3 hrs. It can be burnt in a specially made metal stove. The briquette is placed on the grate of the stove and ignited by putting a fire below by dried woodchips. Once the briquette catches fire at the base, fire spreads uniformly and propagates upward. It can be used for cooking and space heating. This could be an eco-friendly alternative clean source of household fuel to save electricity and wood fuel. Emission of harmful gases from burring briquette is very low as compared to wood and woody biomass which are commonly used by rural people. The calorific value of this briquette is approximately 18-20 MJ/kg and emission of CO, CO2, CH4, NO, and NOx ranges between 0.05-0.1%, 0.1-0.5%, 100-200 ppm, 0.5-3.0 ppm and 0.5-3.5 ppm respectively which is well within the permissible limit.

Beehive Briquettes: Beehive briquettes are mainly charcoal briquettes made from char and clay mud mixed in certain proportion. Mud acts mainly as binding agent and reduces the rate of burning. The beehive briquette is a circular shape briquette having diameter of 145 mm and height of 85 mm with 21 holes of 12 mm diameter. Due to the holes, it looks like beehive, thus the name came Beehive Briquette. Dried beehive briquette produces smokeless blue flame during burning for 2.5 to 3 hrs. It can be burnt in a specially made metal stove. The briquette is placed on the grate of the stove and ignited by putting a fire below by dried woodchips. Once the briquette catches fire at the base, fire spreads uniformly and propagates upward. It can be used for cooking and space heating. This could be an eco-friendly alternative clean source of household fuel to save electricity and wood fuel. Emission of harmful gases from burring briquette is very low as compared to wood and woody biomass which are commonly used by rural people. The calorific value of this briquette is approximately 18-20 MJ/kg and emission of CO, CO2, CH4, NO, and NOx ranges between 0.05-0.1%, 0.1-0.5%, 100-200 ppm, 0.5-3.0 ppm and 0.5-3.5 ppm respectively which is well within the permissible limit.